Category: News

Packaging designers and marketers do a great job in producing food packaging that shows the product inside off to its best. Unfortunately, for mechanical handling companies like WMH, a design that looks good on the supermarket shelf isn’t always the easiest to handle during production. This was the case recently with a large dairy product company who approached WMH to help them re-organise their production line following a supermarket audit.

The plastic pots of desserts and sundaes were quite tall with a very small base which made them very top heavy and prone to tipping. WMH were able to over-come the problem at most transfer points by creating side by side transfers and gently guiding the product from one conveyor to another. There where however several points in the line where end to end transfers were necessary, this lead to one of their designers developing a novel and compact transfer unit to conveyor the pots without tipping. The solution needed to be compact, able to cope with a range of product heights and easy to maintain.

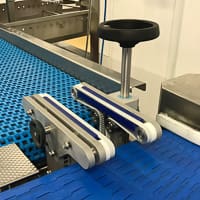

The final solution comprised a pair of parallel driven belts on an adjustable height mechanism, which would support and conveyor the pots under their top lip. All of the drive components for the unit were mounted below conveyor height which helped make the unit as short and compact and possible to be retro-fitted between existing conveyors with very little line disturbance. The unit was manually adjustable via an above belt adjustment wheel to enable quick change overs between the different products.

“We are very happy with the final solution, it looks very neat and works well with the very tricky products” said a spokesman for WMH.

To find out more about this and other bespoke solutions please visit the WMH website at http://www.wmh-uk-ltd.com or call 01579 383788