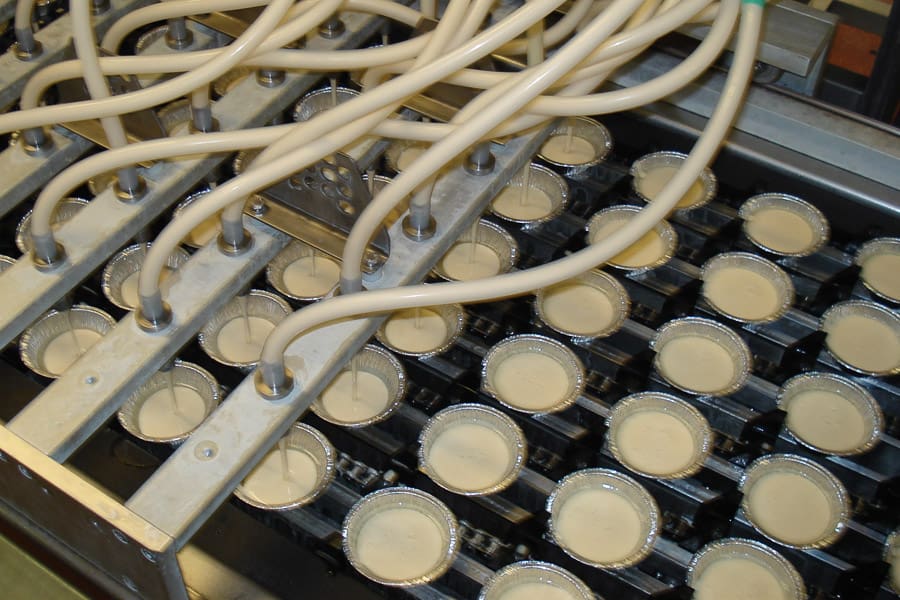

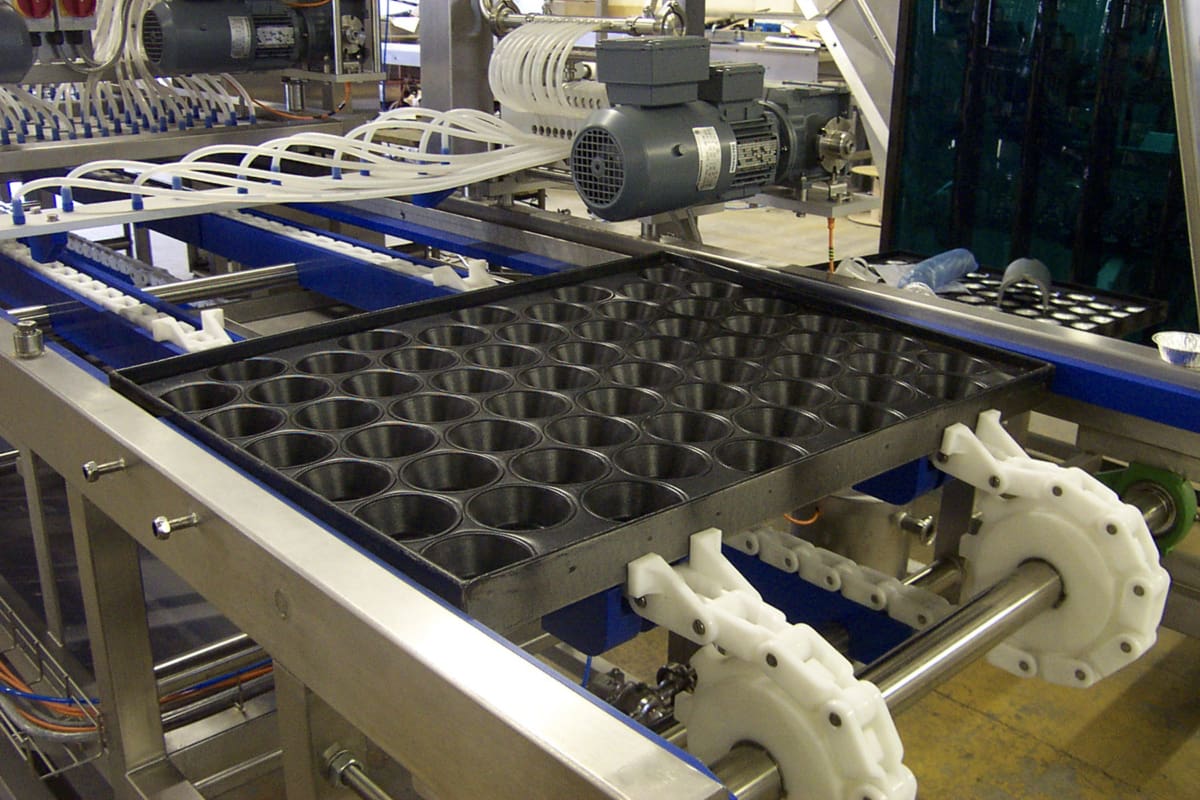

Hygienic multi-lane depositing systems

WMH hygienic multi-lane depositing systems are designed for liquid depositing of hot or cold sauces at high throughputs and with great repeatable accuracy. Our depositors can be supplied as standalone mobile units or can be fully integrated into the production line.

Systems range in size from single pumps with six chambers up to multiple pumps linked together each with up to 32 chambers, and can be stand-alone units or inline systems incorporated into long production lines depositing many products per cycle.

WMH has developed a specialised algorithm control system using servo drive technology to maintain repeatable deposit weight accuracies of +/-0.1g. This system of control is built as standard into all new peristaltic depositing applications and in most cases can be retro-fitted to our older systems.

Key features

All WMH depositing systems are:

- Simple to operate with touch screen interfaces

- Suitable for extended production runs

- Configured for CIP cleaning

WMH understands the demands of a high care environment and designs all machines to be washed down and where possible minimises the areas where build-up of debris can occur, with sloping surfaces and spacing off of bearings and joining brackets and support frames. Prior to specifying a unit WMH will carry out trials with your product to demonstrate the process. For information about this and other WMH Trials Facilities please visit the Trials Facilities page under the Support menu above.

At WMH we aim to build long term relationships with our clients so that we can fully understand your processes and provide the best possible solutions in an ever changing market place.

For more information or to discuss a specific requirement please give one of our sales engineers a call on 01579 383788 or email enquiries@wmh-uk-ltd.com

Typical applications

Pancake Batter | Egg Custard for Quiche | Sauces | Jelly for Pork Pies | Caramel for Desserts | Oil for Yorkshire Puddings | Batter for Yorkshire Puddings | Water | Fruit Juices

View our equipment in action