The UK has some of the strictest food labelling regulations in the world and falling foul of these regulations can be costly for Manufacturers. According to the UK Food Standards agency, product recalls are on the increase and with the cost of mis-labelling product recalls running into the hundreds of thousands of pounds. Ensuring your products are correctly labelled is vital to food businesses.

A quick scan of the government website reveals the size of the problem for product recalls. Whilst the biggest proportion of recalls are due to ingredient mislabelling and product contamination a good number of recalls are down to date and batch code problems. Most of the big supermarkets in the UK have had to recall products over the past 18 months due to date code issues.

Reputation Damage

Not only can product recalls be damaging to the profits of food manufacturers, but they also pose a risk to reputation and product confidence that can take months or years to re-build. The recalling of products and the safe disposal of them add to the financial costs and have an impact on the environment and sustainability of a brand.

The increasing frequency of product recalls due to mislabelling and coding errors highlights the urgent need for more reliable inspection systems. While the financial impact of recalls can be devastating, the long-term damage to consumer confidence and brand sustainability makes prevention even more critical. Many of the UK’s largest supermarkets have faced recalls due to date code issues alone; demonstrating that even seemingly minor errors can have major consequences.

Automation to Solve to Problem

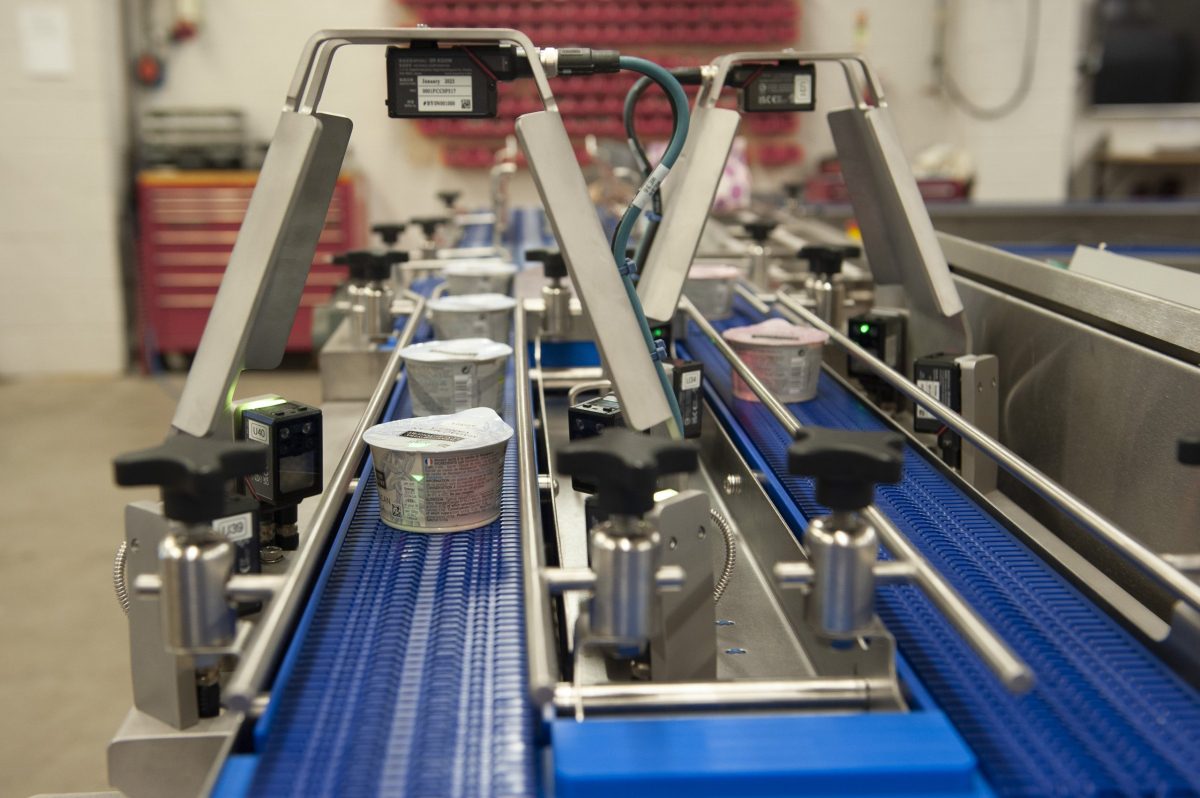

Recognising these challenges, WMH has worked with leading food manufacturers to integrate automated inspection systems that drastically reduce the risk of mis-labelled products leaving the production line. Most recently, WMH’s design team in Cornwall developed a cutting-edge solution for a major dairy producer, strengthening their inspection processes and ensuring product coding errors are detected before distribution.

The system devised by WMH uses four scanners grouped together to view a round pot from different angles to create a single 360º image. This allows a QR code located in the side of the pot to be identified no matter which way round the product is presented. An addition scanner mounted above the line, scans the lid for its corresponding code and the two images are compared by the software to ensure a match.

If a mismatch, is detected the unit can be linked into a reject system for automatic product removal or can stop the line for operator intervention to address the issues upstream. The system runs at a rate of 200 products per minute with a very high degree of accuracy.

By implementing advanced inspection technologies like WMH’s innovative scanning system, food manufacturers can significantly reduce the risk of costly recalls and safeguard their brand’s reputation. As labelling regulations continue to tighten, the ability to detect and correct errors before products reach consumers is more important than ever. Investing in reliable automation ensures compliance, protects profitability, and reinforces customer confidence—creating a more sustainable and secure future for the food industry.